Hydroerosive grinding (HEG) is a form of abrasive flow machining. This process is used for:

- Rounding parts

- Deburring

- Flow calibration

In this process, abrasive fluid is pumped under pressure through the internal geometry of a part. The abrasive particles in the fluid grind the bore hole intersections and inlet edges. Hydroerosive grinding is also very efficient at removing internal burrs as well as smoothing and rounding bore hole intersections. As a result, the part maintains a consistent level of performance throughout its service life. Deburring may be required based on a part’s function as well as for reasons of ergonomics or aesthetics.

Due to the low viscosity of the abrasive fluid, this method can also be used for calibrating holes to a certain flow rate. Throughout the process, the flow rate of the part can be monitored as it increases, so that once it hits precisely the required value, grinding is stopped. This allows the user to set flow rate tolerances of ±1% reliably.

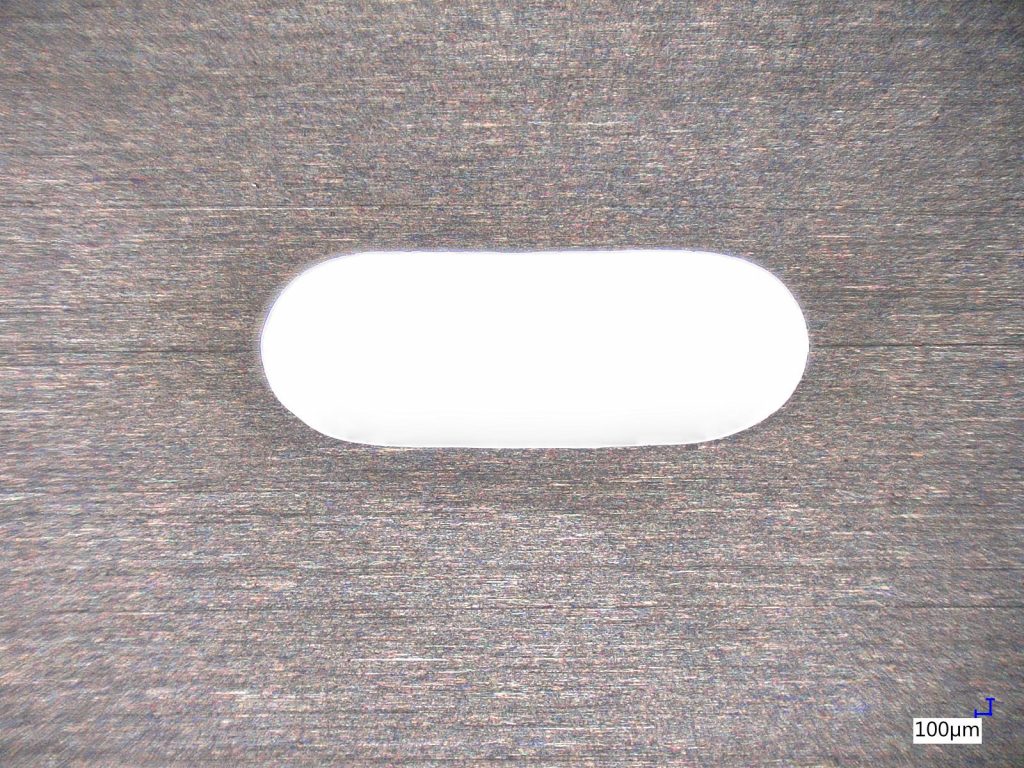

- Titanium before HE grinding

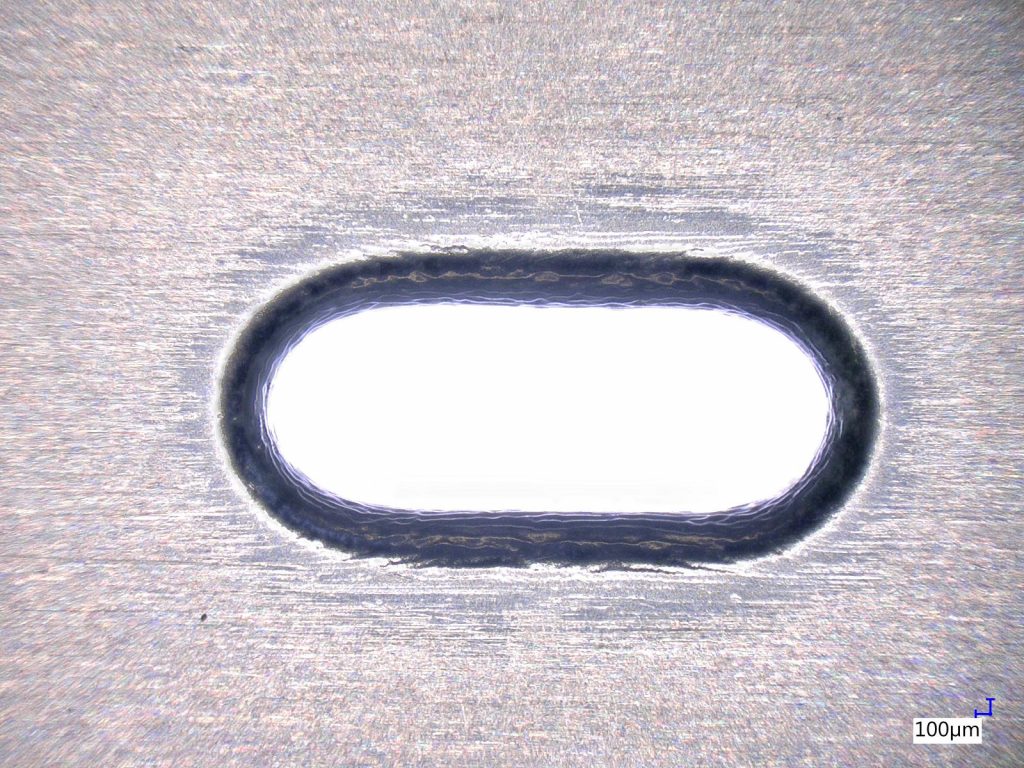

- Titanium after HE grinding

In hydroerosive grinding, abrasive fluids are specially mixed based on each workpiece. These are suspensions. They are non-Newtonian fluids comprised of a carrier (oil or aqueous medium) and the abrasive particles finely distributed within it. The fluids can be optimised for the application by precisely adjusting their viscosity, density, particle concentration, particle size distribution and particle type.

Learn more about our product area and references: