This is followed by fully automated electrical tests (EOL test,) an air leak check and a position check. Finally, a laser labels the metal housing with a DMC and plain text. The robot places the finished components back onto the blister package, which the operator can take away in small load carriers. The assembly process of a control electronics component requires a cycle time of under 13 s. The machine runs autonomously for at least 20 minutes without any operator intervention. Portable control panels allow operators to easily control and monitor the process at every module. Defective assemblies can be efficiently sorted out into reject and rework trays, processed and, if necessary, fed back into the machine.

Highlights

- Fully automated infeeding of individual parts in the blister package stacking system

- Fully automated parts handling with industrial robots

- Fully automated placement of the control electronics assemblies on small load carriers

- At least 20 minutes of autonomic production without operator intervention

- Reject and rework trays for sorting defective assemblies in and out

Processes

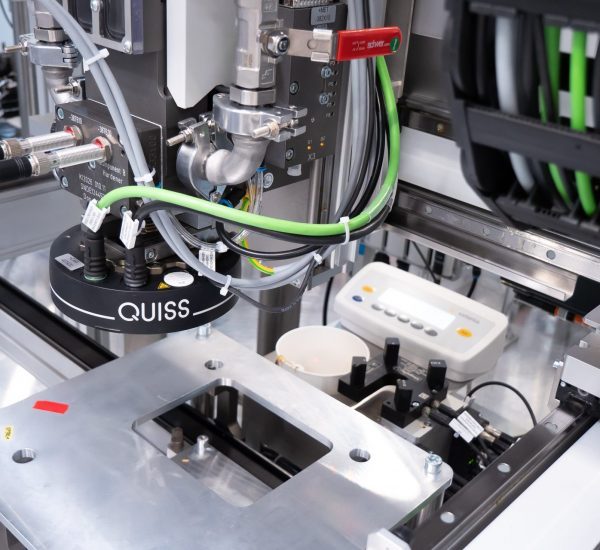

- Dispense (2K)

- Pin inspection

- Assembly processes (presses)

- Leakage test

- Labels

- EOL tests

- Laser marking

- Infrared riveting

- Radial riveting