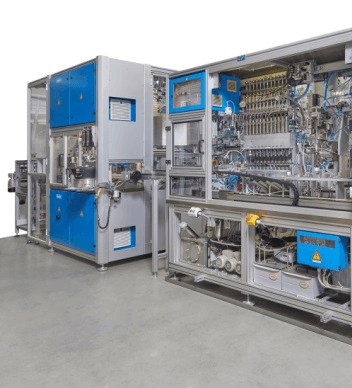

The automatic production line Dry Calibration and Test GDI Injector calibrates and tests PFI injectors. A robot loads the injectors from pallets and puts them onto pucks at a conveyor system. This conveyor connects all substations at the line.

The first substation at the conveyor is a code reading station where the part is identified. After that, the parts are moved to the rotary table where the test substations are located. Before the part arrives at the final dressing stations at the conveyor it can be transferred to the hydraulic audit cell. Within the audit cell the part is supplied with test fuel and tested in static and dynamic mode again. These results are used as reference values to align the dry process to the wet conditions.

Before the robot finally offloads the injector the lower O-ring is mounted and the electrical pins of the terminal are checked by a camera.

Test and final assembly

- Injector coil resistance check

- Static air flow test

- Pre-press of filter tube

- Run-in (air)

- Injector calibration and dynamic tests

- Air leak test

- O-ring assembly

- Optical terminal check

Highlights

- Reduced floor space due to dry calibration process

- The flexible station layout can handle multiple injector outlines without any changeover

- The MATLAB-based signal analysis algorithm is also available in offline mode. In this way, the engineering work can be done at the desktop and helps to reduce the downtime of the machine

- Global type data management and result storage

- Automatic „Mastering“ management

- Offload to different pallet designs

- The scalable machine layout helps to fit also future production demands

- Connection to customer data management

- Wet audit test capability

- The individual flow target correction guarantees a minimum of flow variation

Technical data

General

- Cycle time: 7,5s

- Test pressure: 20, – 5,0 bar

Flow test

- Range: 0,1 – 0,4 g/s (air)

Dynamic test

- Sample rate: 500 kS/s

Leak test

- Leak limit: < 0,15 l/min (air)