Hydrogen is found in fossil raw materials such as natural gas and petroleum as well as in more than half of all known minerals. Under normal conditions, it is a colourless and odourless gas that is about 15 times lighter than air. The light-weight property of the hydrogen molecule also contributes to its great speed of movement.

Content

Hydrogen and E-Mobility

Simply continue to drive with fossil fuels? Seen in the long term, that is no option. On the one hand, Germany has committed itself to international climate protection obligations, and, on the other, the automotive industry would still like to sell its products successfully in the years to come/. The manufacturers have agreed to produce mass-manufactured vehicles with environment-friendly drives until 2035.

For personal road traffic, the E-car with rechargeable battery is being deployed often. This can convert the energy from one kilowatt hour of electricity efficiently. At present, the cost driver is still the battery. However, this is going to change in future. This is why the fuel cell is being treated as the technology of the future since several years – and as another option in the environment-friendly drive mix: With hydrogen, the vehicle can be refuelled within a few minutes – without having to carry any large and heavy battery along with you – a clear and unique benefit.

This is how the fuel cell works

There is an anode and cathode located inside the fuel cell. These are two electrodes permeable to gas that are coated with a catalytic converter. This catalytic converter is generally made from platinum. The electrodes are isolated from one another by a so-called Electrolyte membrane. Gaseous hydrogen is fed to the anode, whereas, in most cases, ambient air is fed to the cathode. Both gases react with one another. Electricity is produced by the potential difference between the two electrodes, and which drives and electric motor. Only water is formed as the waste product that drips out from the exhaust. As a result of this, there are no emissions occurring during driving. However, the hydrogen is not any naturally occurring raw material. A high amount of energy is required for its production.

Since one individual fuel cell does not generate sufficient energy to drive a vehicle, a stack of fuel cells are connected in series. The hydrogen and oxygen from the air fed to each cell is converted to electrical energy. This stack of cells is also called a stack of fuel cells. This generally consists of bipolar plates, membrane electrode assemblies (MEAs), seals and the bracing system.

The hydrogen combustion engine

However, hydrogen can not only be used in the fuel cell. Even conventional combustion engines can be driven flexibly with the chemical element. Compared to a modern electric car, the efficiency is also considerably lower: While a purely E-vehicle brings about 80 to 90 per cent of one kilowatt hour of electricity as drive power on the road, a hydrogen car needs about two to three times as much electricity for the same route.

Hydrogen – the self-sufficient solution

According to the electricity grid operator EnBW, the number of E-cars that are presently supplied with electricity via private wall boxes or public charging stations is already a challenge today. The electricity grid operators have the task of having to supply the entire fleet of cars with electricity in Germany. According to EnBW, this would mean about 40 million battery-operated cars or more. The power grid today is technically not yet designed for this. In fact, there would tentatively be adequate power sockets in the next ten to twenty years, but probably adequate electricity cannot be provided.

This is where the benefits of hydrogen are impressive. The reason being that the driver can refuel his car at a conventional fuel station in a few minutes with hydrogen. While driving, he generates his electricity quite simply on his own. This self-sufficient solution is viable especially in the utility vehicle range with long routes of more than 1,000 kilometres. By omitting the battery, the total weight of the vehicle drops substantially, which has an extremely favourable impact on its range. There is also another benefit here: Refuelling with hydrogen takes place considerably faster than recharging a battery. This is particularly relevant for utility vehicles. In this way, the fuel cell or a combination of fuel cell, battery and E-motor a permanent integral constituent of future mobility.

Hydrogen drive and electric car in comparison

| THE PURELY E-CAR WITH RECHARGEABLE BATTERY | THE CAR DRIVEN BY HYDROGEN | |

| Energy balance | Energy can be converted more efficiently | — |

| Weight | — | Lighter, because no rechargeable battery has to be carried along |

| Range | — | Higher, since it is lightweight and the vehicle produces its electricity during travel |

| Tank duration | Several hours (at fast-charging pillars, about 30 minutes) | A few minutes |

| Refuelling options | Is being expanded continuously, and this is being supplemented by wall boxes | Not well widespread in every country |

| Procurement and maintenance costs | — | Higher due to complex fuel cell |

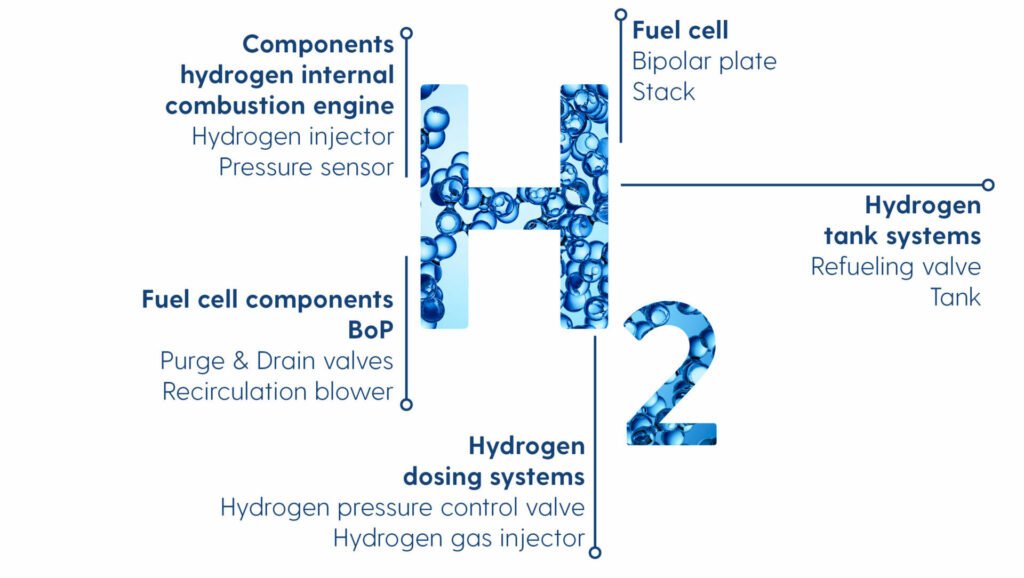

How Sonplas is supporting manufacturers

Sonplas is relying on more than 25 years of specialised skills in fuel injection. As a service provider, Sonplas offers the opportunity of testing hydrogen-carrying components in an independent test bench for functionality and service life. Moreover, an in-house fuel laboratory, feasibility analyses and product tests, still supplement the range of items for our customers.

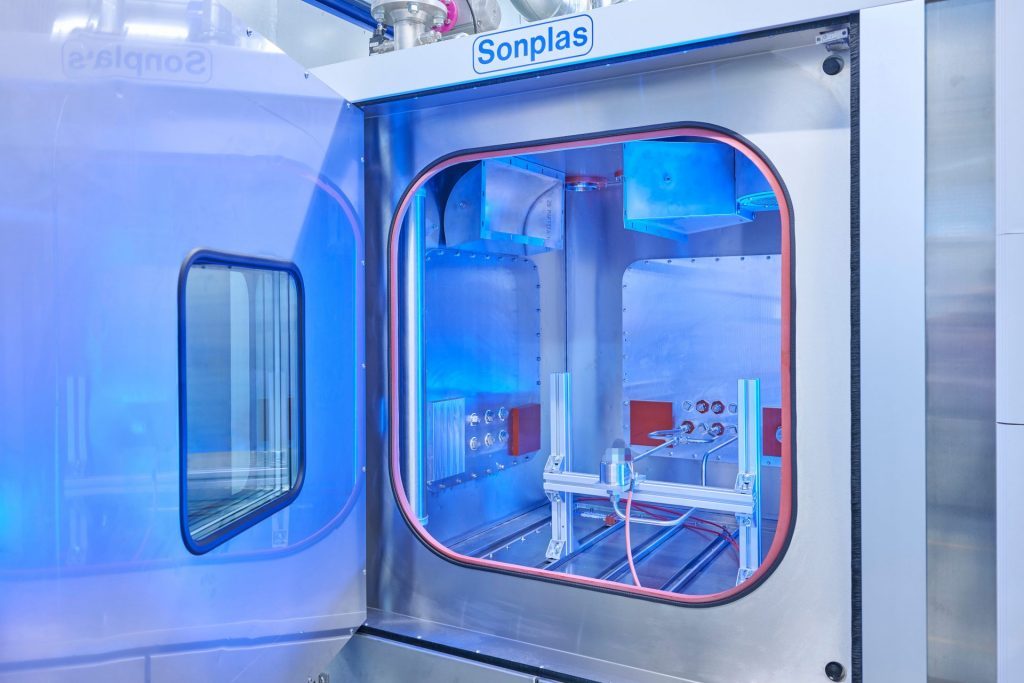

The in-house hydrogen test center of Sonplas GmbH

Hydrogen plays an important role for clean mobility since in contrast to fossil fuels, no CO2 emissions are released when driving with green hydrogen. The energy source is converted into electricity with the help of a fuel cell, and this drives an electric motor. Only steam is discharged from the exhaust.

In order to ensure mass manufacture capability of a hydrogen drive, accurate functional tests are required on hydrogen-carrying components. We can fall back on more than 25 years of experience in the injection of conventional fuels such as petrol and diesel, and we see numerous synergies in the test processes and in the equipment for hydrogen-carrying components. In this way, we could transfer our comprehensive know-how in this technology of the future with minor cost and effort, and develop the H2 test bench – and supplement our range of products with a functional and service life testing of hydrogen-carrying components. Even temporal high-resolution measurement of the injection rates can be determined in this test bench thanks to the measuring instrument developed in-house. The tests take place in a thermal chamber in which our H2 test bench controls the temperature of your components during the test. The temperature range starts with minus 40 and reaches up to plus 130 degrees Celsius. With the help of another module, the hydrogen can be conditioned to various values of temperature. The requirements for a vehicle may vary considerably in different regions and under varied operating conditions.

In addition, we have formulated a concept that is still in the implementation stage. With this, we shall be able to test your components in continuous mode of operation. That may be 100 or even 1,000 hours. With this method, we intercept the hydrogen that passes through the component again, collect it and put it back into use. As a result of this, you reduce costs considerably and also conserve the environment.

Costs at a glance

It is not always apparent before a project regarding the pressure needed, the mass flows or functions that are necessary. These may undergo a change during the project. In order that you have a clear overview of your investments from the very beginning, we are offering you a modular system with our H2 test bench starting from 2023. You shall receive a special machine that you can retrofit and reconfigure according to your requirements.

As a service provider, we are also offering you the option of testing your components in-house at our premises. Keep your costs in check and reserve only the testing time that you require. Benefit from the valuable knowledge and findings about your products – or for a planned test bench project that you are presently working on. Our experts are available at your service with their comprehensive know-how.

The three pillars of knowledge

Contact us!

Our

FAQs

Definitely. Hydrogen is already a source of energy for the future. Based on the finite quantities of fossil fuels such as oil and gas, alternative energy sources are in demand in order to implement the change in form of energy successfully.

With so-called grey hydrogen, it is split from a fossil hydrocarbon. This generally takes place with the help of steam reforming somewhat like from natural gas. In the process, the natural gas reacts with steam and hydrogen and CO2 are formed, which escape into the atmosphere.

During the production of blue hydrogen, in contrast to green hydrogen, the CO2 emissions occurring with the CCS technology (Carbon Capture and Storage) are separated and stored. In this way, no CO2 escapes into the atmosphere.

Turquoise hydrogen is also produced from fossil natural gas. Solid carbon is produced with pyrolysis. In this way, no gas separation is necessary.

Green hydrogen is produced on the basis of renewable energies. This generally takes place with electrolysis of water. In the process, water is decomposed into hydrogen and oxygen by using electricity. Since the energy originates from renewable energies, hydrogen can be produced in a CO2 neutral manner.

In its pure form, hydrogen is an invisible, odourless and non-toxic gas that is lighter than air.

Green hydrogen is as environmental-friendly as green electricity from which it is produced. The disadvantage: You need a large amount of energy in order to compress hydrogen.

The greatest disadvantage is the low overall efficiency compared to a pure E-car/. A large amount of energy is required in order to provide hydrogen.

As a service provider, Sonplas offers the opportunity of testing hydrogen-carrying components in-house at their premises for functionality and service life. In this way, you can keep your costs in check and reserve only the testing time that you require.

In addition, you can benefit from the valuable knowledge and findings about your products – or for a planned test bench project that you are presently working on. The experts at Sonplas are available at your service with comprehensive know-how.