Separation | Notching | Slitting

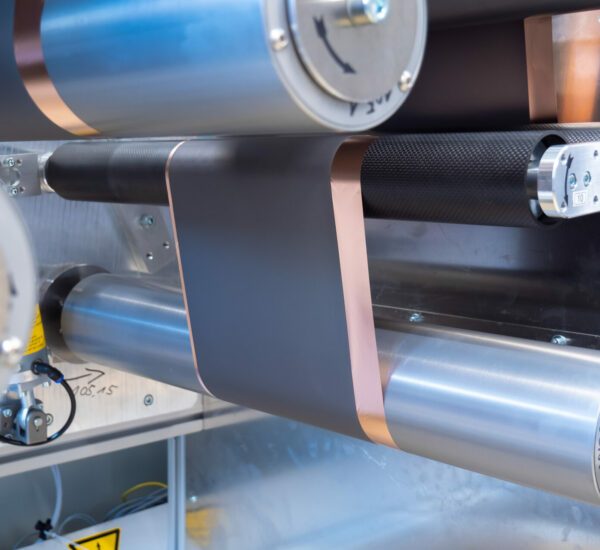

Laser cutting (Laser notching) of electrode material is one of the most important processes of battery cell production, which has direct impact on the quality and lifespan of the battery cell. With the innovative laser process from Sonplas, particles are eliminated and you can achieve an optimized quality of the cut edge at high processing speed. The modular concept enables the use of both a roll-to-roll process, in which the edges (tab and bottom side) of the electrode material are laser processed as well as a roll-to-sheet process (separating mother roll into multiple daughter rolls) in which the individual electrodes are cut out from the roll material and put into magazines.

We invite you to do test runs and sample production with your material on our flexible demonstrator in our laboratory at any time. Please contact us.

Learn more about our innovative laser process:

Mission 180

- Materials: C / SiC / NMC / LFP / anode + cathode, applicable for LIB / SSB / SIB

- Laser cutting speed of up to 3m/s or 180m/min depending on the material possible

- Optimised laser cutting edge and elimination of particles for best quality and lifespan of the battery cell

- Flexible options for use:

- Roll-to-roll (Notching)

- Roll-to-sheet (Separation) with placing in magazines or combining with downstream processes

Technical data

- Up to 180m/min

- Area up to 700x700mm

- Excellent web tension control ±1N

- Position tolerance down to ±50µm

Processes

- Roll-to-roll (defined tape tensioning, winding quality)

- Laser cutting with laser configuration depending on the electrode material

- Slitting

- Vision inspection