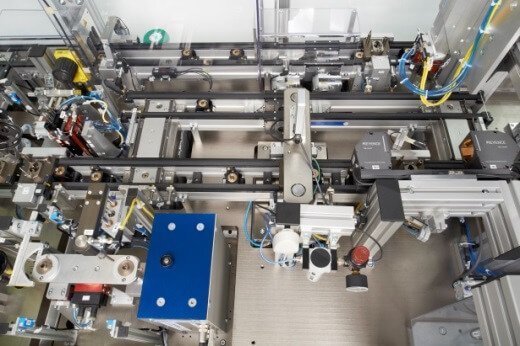

Fully automatic injector assembly.

The individual parts of the injector are fed by pallets on a conveying system of the machine. The installation is fully automated by three robot systems. To compensate the variation of the items all the relevant dimensions are controlled by integrated measuring stations and observed during the assembly. This guarantees a constant output quality.

Highlights

- Fully automated injector assembly

- Determination of all part necessary dimensions during the assembly

- Intuitive user software in Windows 7

- Graphical presentation of all measurement results

- Automatic monitoring of measuring systems by cyclic tests of master parts

- Storage of all test specifications and results and production data in a server-based database to carry out extensive evaluations

Technical data

- Cycle time: 22 Seconds per part

- Dimensions: W: 2,7 m x L: 6 m x H 2,2 m

- Spring length measurement (+/- 10 µm @ 75N)

- Measuring station for inner and outer diameter (inner diameter +/- 0,04 µm) (outer diameter +/- 0,25 µm)

- Press-in station(+/- 60 µm)

- Measuring station for part height (+/- 1µm)