The GDI injector dry calibration and testing facility enables the research and development department to analyse the behaviour of low-pressure petrol injectors in a “dry” state.

The data and findings obtained will initially be used to develop an adjustment process under laboratory conditions, which can then be used in production and should help to manufacture the injector faster and more cost-effectively.

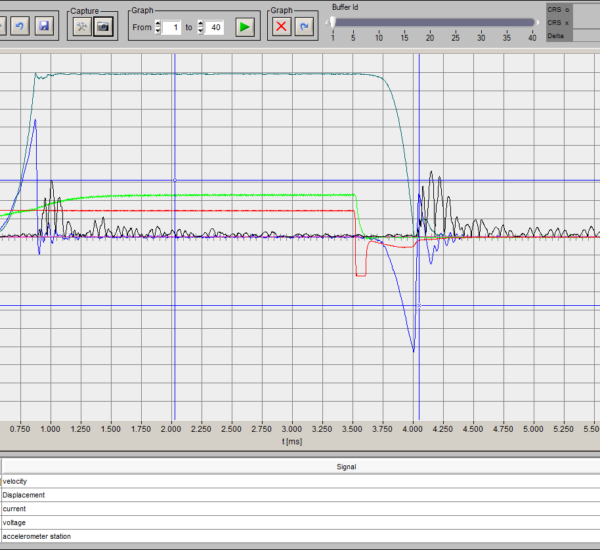

In order to obtain detailed data sets, several measuring systems are integrated into the test device, the values of which are recorded synchronously by a fast data acquisition system. The recorded curves are analysed using the MATLAB data analysis tool.

By separating data recording and analysis, post-processing of data sets with different specifications and algorithms is possible at any time.

Highlights

Data recording with up to 1MS/s

Sequence control via LabView interface

Signal recording of:

- Injector voltage

- Injector current

- Acceleration sensor

- Displacement and velocity signal of the laser vibrometer

Analysing the measurement data using MATLAB

Dynamic and static flow measurement with air or nitrogen

Servo-driven adjustment device with force and displacement monitoring

Flexible design for different injector geometries

Technical data

- Pressure range: 0.1 – 6 bar

- Flow range: < 1 g/s

- Period duration: > 20 ms

- Max. Setting force: < 1kN