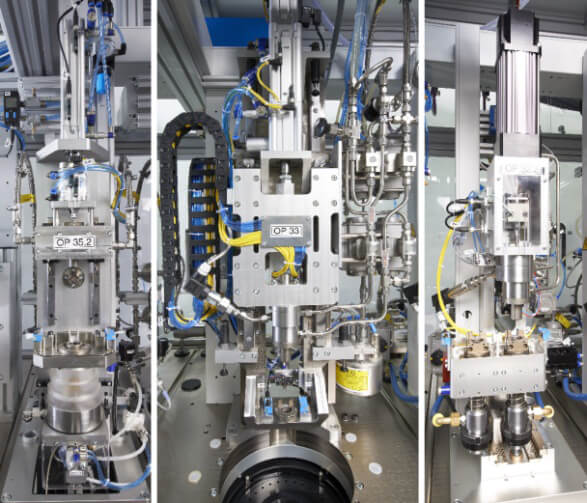

– robotic loader – run in – flow calibration – flow test – spray test – liquid leak test – flushing –

The Production Line GDI Injectors is an automatic system for calibration and test of high-pressure solenoid fuel injectors.

The operation starts with loading the injector by means of a robot into a rotary dial. After reading the serial code (DMC), the injector enters the calibration unit. In the module the injectors are driven for about 150000 cycles in order to run-in and therefore stabilize the part.

The injector will be calibrated to a target flow, two additional flows can be rechecked at different test conditions. The next work process verifies the spray geometry of the injector by analyzing a shadowgraph taken image. Within the last performed work step the seat leakage will be tested with the patented liquid leak test.

Before unloading, the injector will be flushed out with air, so that the part will exit the production equipment in dry condition.

Finally, good parts will be placed into pallets, scraps will be sorted into the dedicated scrap rails.

Highlights

- Scalable layout: the production capacity can be easily adjusted according to customer requirements.

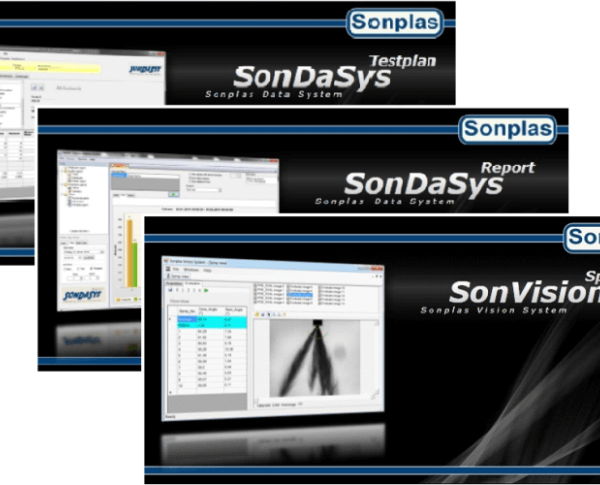

- Fully traceable production data handling with SonDaSys-Testplan

- Fully traceable result data storage and production control with SonDaSys-Report

- Integrated Spray vision inspections software (SonVision) – a Sonplas developed software package

- Injector driver board from Sonplas (Universal-Solenoid-Driver) – a wide range of current profiles can be generated (up to three independent voltage supplies are possible).

- Automatic type adjustment

- Automatic „Mastering“ – a possibility to control the production quality online

- Uplink to customers database

- Editable scrap part sorting

- Compact design

Technical data

General:

- Max. run-in time per unit: < 320 sec.

- Production rate: 1.1 mio./year (15 sec. cycle time)

- Standalone production: < 40min

Flow test:

- Pressure range: 20 …300 bar

- Flow range: 0.3 …16.0 g/s

- Flow accuracy: 0.1 %

Spray test:

- Pressure range: 20…300 bar

- Vision software: SonVision inlcuding Spray package

Leak test:

- Pressure range: 20 …200 bar

- Leak rate: < 10 µl/min